Read the article now:

October 17, 2020 / Source: www.contorion.de

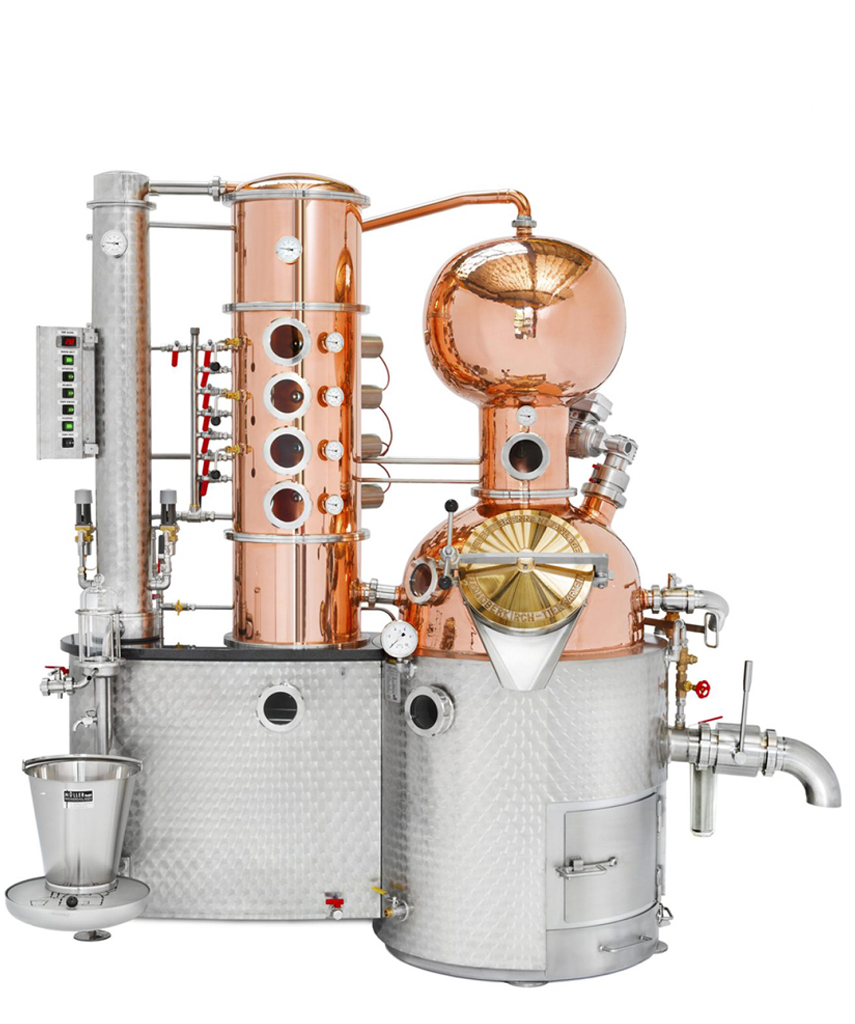

Since 1929, the Müller Distillery Plants craft business has existed in Tiergarten, Baden. Using traditional methods, high-quality equipment is produced here that inspires distillers around the world. Craft and schnapps? Let's take a closer look!

Vineyards grow on the slopes, fruit trees and berry bushes line the plain. Some of the grapes, plums, apples, cherries and the like that grow here have been processed into brandies and spirits for centuries. The region has several hundred thousand distilleries.

The distillery culture in the Black Forest dates back to a law passed at the end of the 18th century by Princess Maria Theresa - Baden-Württemberg and Bavaria were part of Austria at the time. As an additional source of income, she allowed the beleaguered farmers in her realm to produce and sell schnapps. The law has endured to this day: While no high-proof alcohol except gin may be produced without a license in the north, it is permitted in southern Germany.

Family business since 1929

In the midst of the most important distillery region of Germany, is home to the craft company Müller Brennereianlagen. In the Ortenau district, the company has existed since the beginning of the 20th century. At that time, the great-grandfather of today's managing director Bernhard Müller manufactured horseshoes, wheels, barrels and all kinds of components for agricultural machinery. Just one generation later, the company specialized in distillery equipment

Today, the company has about 15 employees. The sons of the boss, Lukas and Sebastian Müller, are also active in the company. In addition to studying business administration and engineering, they have also completed their training - Lukas is a plant engineer, Sebastian is a burner. Their most important tasks are marketing and overseas sales. They accompany the finished plants to the customer, assemble them on site and instruct the customer in their use.

From the workshop to their destination, distillers often have a long way to go. They go to the USA, Australia, Scotland, Italy, Spain, Canada, the Caribbean Islands, Russia, Japan and India. In short: The whole world brews with Müller distillery ingredients from the Black Forest.

"Our patents make us world-famous".

Sebastian Müller and his two brothers form the fourth generation of the family business. International sales are one of his main tasks. Together with the customers, he plans the plant, commissions it on site with the customer and teaches him the technology of the art of distillation.

Your equipment is in demand all over the world. How do customers from Australia or Haiti, for example, find you?

Many come through the search on the Internet. They search for "craft distillery" and so come to our website. We as a German craft company are quite specialized in this field. When we talk about Craft Distilling, we are talking about filling volumes from 100 to 2,000 liters. But our equipment is also characterized by our innovations. We have been on the market for a very long time and the plants have been and continue to be constantly developed. We have developed a special column technology, automatic control and so on. Likewise, plants "Made in Germany" are still very much in demand.

Are there different "off the shelf" models that you just keep building, or are they custom designs?

We build distilleries of various sizes for a wide range of products. Be it fruit brandy, whisky, gin, rum - in fact, any product. Each plant is built according to customer requirements. For example, we look at whether the alcohol collection tanks are to be placed on the left or right and where the outlet is located. Some customers want a decorative show distillery with lots of beautiful copper surfaces - we then have to take that into account. The type of heating is also a very important issue. There are variants with wood, oil, gas, electric or steam.

How the plant is operated later is also relevant. Is it a distiller who relies on his gut feeling when distilling? Then he doesn't need electrical control. Or is it someone who always wants to distill exactly the same product in high quantities? Then we have automatic controls with recipe options. So at the end of the day, no plant leaves here looking like a predecessor.

You have been awarded by the Chamber of Crafts for combining artisanal production with advanced technology. You also call your distilleries the most advanced in the world. Why is that?

We focus very strongly on innovation. We also have a number of patents, particularly with regard to column technology, which we are very proud of and which make us world-famous. Perhaps to help you understand: a column helps the distiller to distinguish good alcohols from bad ones. When mash is fermented, it produces runnings, middle runs and runnings, fusel oils. Middle runs are the heart of what we want to have in the glass later. These must be cleanly separated from the others. That is the task of the burner. And we support it in this by installing modern columns. In addition, our plants have digital control with recipe option, automatic heating with steam control valve, automatic cooling and much more.

What materials are used in the construction of a distillery plant and why?

Our main materials are copper and stainless steel, less often we use steel. On the one hand, copper is a very good heat conductor. But even more important is its catalytic effect. During fermentation, prussic acid is formed, especially in fruit mashes with stones - be it plums, cherries or apricots. Under the influence of light, this can be converted into ethyl carbamate, a carcinogenic substance. The copper surface helps to bind the prussic acid. Copper also binds various acids and sulfurous substances. If a distillate were produced in a pure stainless steel plant, it would be undrinkable in most cases. The copper surface is therefore elementary for the distillation process.

A lot of your work is handmade. Why do you stick to the traditional way of working?

Craftsmanship plays a very important role in our company, because it simply shows that the equipment is very durable as a result. The longevity comes from the special processing of the copper.

We still form the copper by hand with a power converter. In the process, the copper is compressed, which gives us a consistent, neat material density. The certainly simpler and cheaper alternative would be to draw the material or press copper parts. Unfortunately, this destroys the structure of the copper. We avoid this by working by hand. Then the entire copper surface is hammered. This way it is not vulnerable to acid or other substances in the mash and remains clean and smooth for a long time.

The magazine On site from Contorion writes under the title "Hammered in the Black Forest, known worldwide". about us.

Je now learn more, on the pages of Contorion

Read the article now:

October 17, 2020 / Source: www.contorion.de

Since 1929, the Müller Distillery Plants craft business has existed in Tiergarten, Baden. Using traditional methods, high-quality equipment is produced here that inspires distillers around the world. Craft and schnapps? Let's take a closer look!

Vineyards grow on the slopes, fruit trees and berry bushes line the plain. Some of the grapes, plums, apples, cherries and the like that grow here have been processed into brandies and spirits for centuries. The region has several hundred thousand distilleries.

The distillery culture in the Black Forest dates back to a law passed at the end of the 18th century by Princess Maria Theresa - Baden-Württemberg and Bavaria were part of Austria at the time. As an additional source of income, she allowed the beleaguered farmers in her realm to produce and sell schnapps. The law has endured to this day: While no high-proof alcohol except gin may be produced without a license in the north, it is permitted in southern Germany.

Family business since 1929

In the midst of the most important distillery region of Germany, is home to the craft company Müller Brennereianlagen. In the Ortenau district, the company has existed since the beginning of the 20th century. At that time, the great-grandfather of today's managing director Bernhard Müller manufactured horseshoes, wheels, barrels and all kinds of components for agricultural machinery. Just one generation later, the company specialized in distillery equipment

Today, the company has about 15 employees. The sons of the boss, Lukas and Sebastian Müller, are also active in the company. In addition to studying business administration and engineering, they have also completed their training - Lukas is a plant engineer, Sebastian is a burner. Their most important tasks are marketing and overseas sales. They accompany the finished plants to the customer, assemble them on site and instruct the customer in their use.

From the workshop to their destination, distillers often have a long way to go. They go to the USA, Australia, Scotland, Italy, Spain, Canada, the Caribbean Islands, Russia, Japan and India. In short: The whole world brews with Müller distillery ingredients from the Black Forest.

"Our patents make us world-famous".

Sebastian Müller and his two brothers form the fourth generation of the family business. International sales are one of his main tasks. Together with the customers, he plans the plant, commissions it on site with the customer and teaches him the technology of the art of distillation.

Your equipment is in demand all over the world. How do customers from Australia or Haiti, for example, find you?

Many come through the search on the Internet. They search for "craft distillery" and so come to our website. We as a German craft company are quite specialized in this field. When we talk about Craft Distilling, we are talking about filling volumes from 100 to 2,000 liters. But our equipment is also characterized by our innovations. We have been on the market for a very long time and the plants have been and continue to be constantly developed. We have developed a special column technology, automatic control and so on. Likewise, plants "Made in Germany" are still very much in demand.

Are there different "off the shelf" models that you just keep building, or are they custom designs?

We build distilleries of various sizes for a wide range of products. Be it fruit brandy, whisky, gin, rum - in fact, any product. Each plant is built according to customer requirements. For example, we look at whether the alcohol collection tanks are to be placed on the left or right and where the outlet is located. Some customers want a decorative show distillery with lots of beautiful copper surfaces - we then have to take that into account. The type of heating is also a very important issue. There are variants with wood, oil, gas, electric or steam.

How the plant is operated later is also relevant. Is it a distiller who relies on his gut feeling when distilling? Then he doesn't need electrical control. Or is it someone who always wants to distill exactly the same product in high quantities? Then we have automatic controls with recipe options. So at the end of the day, no plant leaves here looking like a predecessor.

You have been awarded by the Chamber of Crafts for combining artisanal production with advanced technology. You also call your distilleries the most advanced in the world. Why is that?

We focus very strongly on innovation. We also have a number of patents, particularly with regard to column technology, which we are very proud of and which make us world-famous. Perhaps to help you understand: a column helps the distiller to distinguish good alcohols from bad ones. When mash is fermented, it produces runnings, middle runs and runnings, fusel oils. Middle runs are the heart of what we want to have in the glass later. These must be cleanly separated from the others. That is the task of the burner. And we support it in this by installing modern columns. In addition, our plants have digital control with recipe option, automatic heating with steam control valve, automatic cooling and much more.

What materials are used in the construction of a distillery plant and why?

Our main materials are copper and stainless steel, less often we use steel. On the one hand, copper is a very good heat conductor. But even more important is its catalytic effect. During fermentation, prussic acid is formed, especially in fruit mashes with stones - be it plums, cherries or apricots. Under the influence of light, this can be converted into ethyl carbamate, a carcinogenic substance. The copper surface helps to bind the prussic acid. Copper also binds various acids and sulfurous substances. If a distillate were produced in a pure stainless steel plant, it would be undrinkable in most cases. The copper surface is therefore elementary for the distillation process.

A lot of your work is handmade. Why do you stick to the traditional way of working?

Craftsmanship plays a very important role in our company, because it simply shows that the equipment is very durable as a result. The longevity comes from the special processing of the copper.

We still form the copper by hand with a power converter. In the process, the copper is compressed, which gives us a consistent, neat material density. The certainly simpler and cheaper alternative would be to draw the material or press copper parts. Unfortunately, this destroys the structure of the copper. We avoid this by working by hand. Then the entire copper surface is hammered. This way it is not vulnerable to acid or other substances in the mash and remains clean and smooth for a long time.

The magazine On site from Contorion writes under the title "Hammered in the Black Forest, known worldwide". about us.

Read the article now:

October 17, 2020 / Source: www.contorion.de

Since 1929, the Müller Distillery Plants craft business has existed in Tiergarten, Baden. Using traditional methods, high-quality equipment is produced here that inspires distillers around the world. Craft and schnapps? Let's take a closer look!

Vineyards grow on the slopes, fruit trees and berry bushes line the plain. Some of the grapes, plums, apples, cherries and the like that grow here have been processed into brandies and spirits for centuries. The region has several hundred thousand distilleries.

The distillery culture in the Black Forest dates back to a law passed at the end of the 18th century by Princess Maria Theresa - Baden-Württemberg and Bavaria were part of Austria at the time. As an additional source of income, she allowed the beleaguered farmers in her realm to produce and sell schnapps. The law has endured to this day: While no high-proof alcohol except gin may be produced without a license in the north, it is permitted in southern Germany.

Family business since 1929

In the midst of the most important distillery region of Germany, is home to the craft company Müller Brennereianlagen. In the Ortenau district, the company has existed since the beginning of the 20th century. At that time, the great-grandfather of today's managing director Bernhard Müller manufactured horseshoes, wheels, barrels and all kinds of components for agricultural machinery. Just one generation later, the company specialized in distillery equipment

Today, the company has about 15 employees. The sons of the boss, Lukas and Sebastian Müller, are also active in the company. In addition to studying business administration and engineering, they have also completed their training - Lukas is a plant engineer, Sebastian is a burner. Their most important tasks are marketing and overseas sales. They accompany the finished plants to the customer, assemble them on site and instruct the customer in their use.

From the workshop to their destination, distillers often have a long way to go. They go to the USA, Australia, Scotland, Italy, Spain, Canada, the Caribbean Islands, Russia, Japan and India. In short: The whole world brews with Müller distillery ingredients from the Black Forest.

"Our patents make us world-famous".

Sebastian Müller and his two brothers form the fourth generation of the family business. International sales are one of his main tasks. Together with the customers, he plans the plant, commissions it on site with the customer and teaches him the technology of the art of distillation.

Your equipment is in demand all over the world. How do customers from Australia or Haiti, for example, find you?

Many come through the search on the Internet. They search for "craft distillery" and so come to our website. We as a German craft company are quite specialized in this field. When we talk about Craft Distilling, we are talking about filling volumes from 100 to 2,000 liters. But our equipment is also characterized by our innovations. We have been on the market for a very long time and the plants have been and continue to be constantly developed. We have developed a special column technology, automatic control and so on. Likewise, plants "Made in Germany" are still very much in demand.

Are there different "off the shelf" models that you just keep building, or are they custom designs?

We build distilleries of various sizes for a wide range of products. Be it fruit brandy, whisky, gin, rum - in fact, any product. Each plant is built according to customer requirements. For example, we look at whether the alcohol collection tanks are to be placed on the left or right and where the outlet is located. Some customers want a decorative show distillery with lots of beautiful copper surfaces - we then have to take that into account. The type of heating is also a very important issue. There are variants with wood, oil, gas, electric or steam.

How the plant is operated later is also relevant. Is it a distiller who relies on his gut feeling when distilling? Then he doesn't need electrical control. Or is it someone who always wants to distill exactly the same product in high quantities? Then we have automatic controls with recipe options. So at the end of the day, no plant leaves here looking like a predecessor.

You have been awarded by the Chamber of Crafts for combining artisanal production with advanced technology. You also call your distilleries the most advanced in the world. Why is that?

We focus very strongly on innovation. We also have a number of patents, particularly with regard to column technology, which we are very proud of and which make us world-famous. Perhaps to help you understand: a column helps the distiller to distinguish good alcohols from bad ones. When mash is fermented, it produces runnings, middle runs and runnings, fusel oils. Middle runs are the heart of what we want to have in the glass later. These must be cleanly separated from the others. That is the task of the burner. And we support it in this by installing modern columns. In addition, our plants have digital control with recipe option, automatic heating with steam control valve, automatic cooling and much more.

What materials are used in the construction of a distillery plant and why?

Our main materials are copper and stainless steel, less often we use steel. On the one hand, copper is a very good heat conductor. But even more important is its catalytic effect. During fermentation, prussic acid is formed, especially in fruit mashes with stones - be it plums, cherries or apricots. Under the influence of light, this can be converted into ethyl carbamate, a carcinogenic substance. The copper surface helps to bind the prussic acid. Copper also binds various acids and sulfurous substances. If a distillate were produced in a pure stainless steel plant, it would be undrinkable in most cases. The copper surface is therefore elementary for the distillation process.

A lot of your work is handmade. Why do you stick to the traditional way of working?

Craftsmanship plays a very important role in our company, because it simply shows that the equipment is very durable as a result. The longevity comes from the special processing of the copper.

We still form the copper by hand with a power converter. In the process, the copper is compressed, which gives us a consistent, neat material density. The certainly simpler and cheaper alternative would be to draw the material or press copper parts. Unfortunately, this destroys the structure of the copper. We avoid this by working by hand. Then the entire copper surface is hammered. This way it is not vulnerable to acid or other substances in the mash and remains clean and smooth for a long time.