True craftsmanship provides high quality

Distillery units made in Germany

Premium craftsmanship manufacturing

for distillers with high expectations

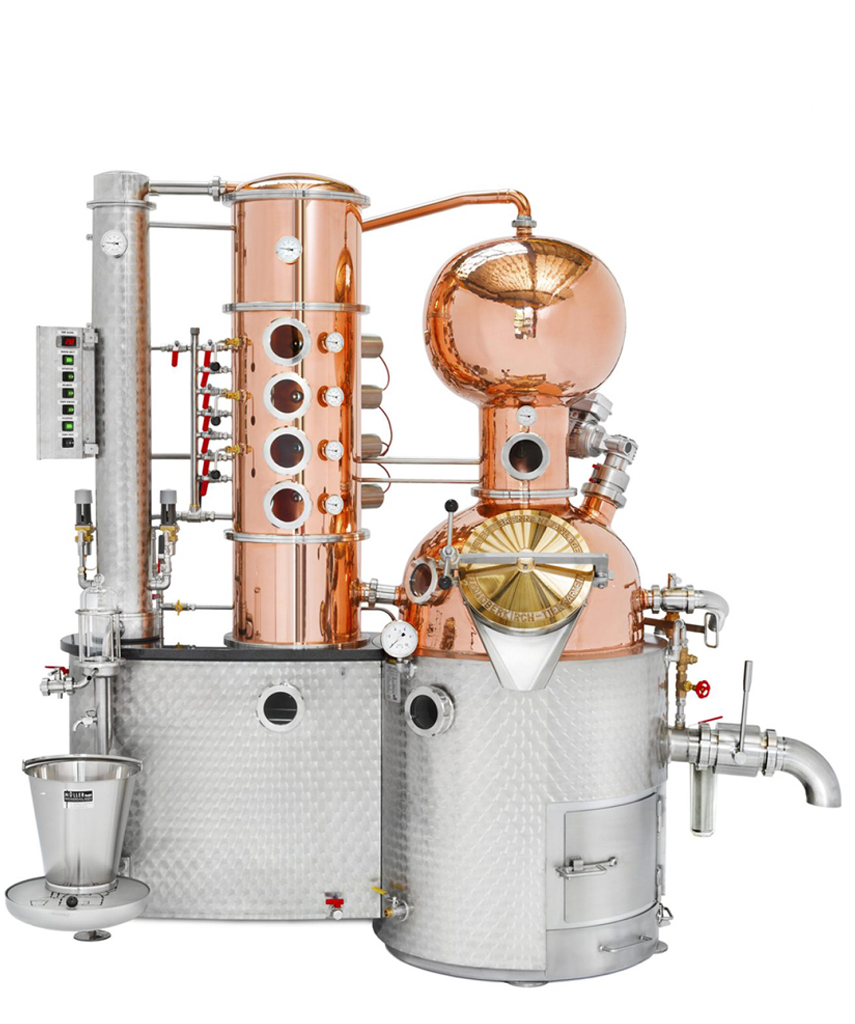

Our distillation units are all hand-built from the highest quality materials in our workshop in Southern Germany. They are made using copper specific, manual handling techniques and a metal forming machine, hammer, welder, polisher as well as blood, sweat and tears. This traditional and time-consuming manufacturing method warrants a consistent material thickness throughout the copper Pot Still and an outstanding longevity of our units.

Copper specific shaping

We manufacture our pot still from pure copper; SF-CU certified and tested material. The raw plates are hemispherically formed by hand using a planishing hammer before the surface is treated and hardened with the hammer finish technique. This hammering, a time-consuming and labour intensive step in the manufacturing process solidifies the structure of the copper. Important, because the copper will be heavily stressed during its future applications of catalytic efficiency, the reaction between fruit acids and the copper. The master technique of the copper forming creates a smooth surface, durability and provides maximum strength.

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information