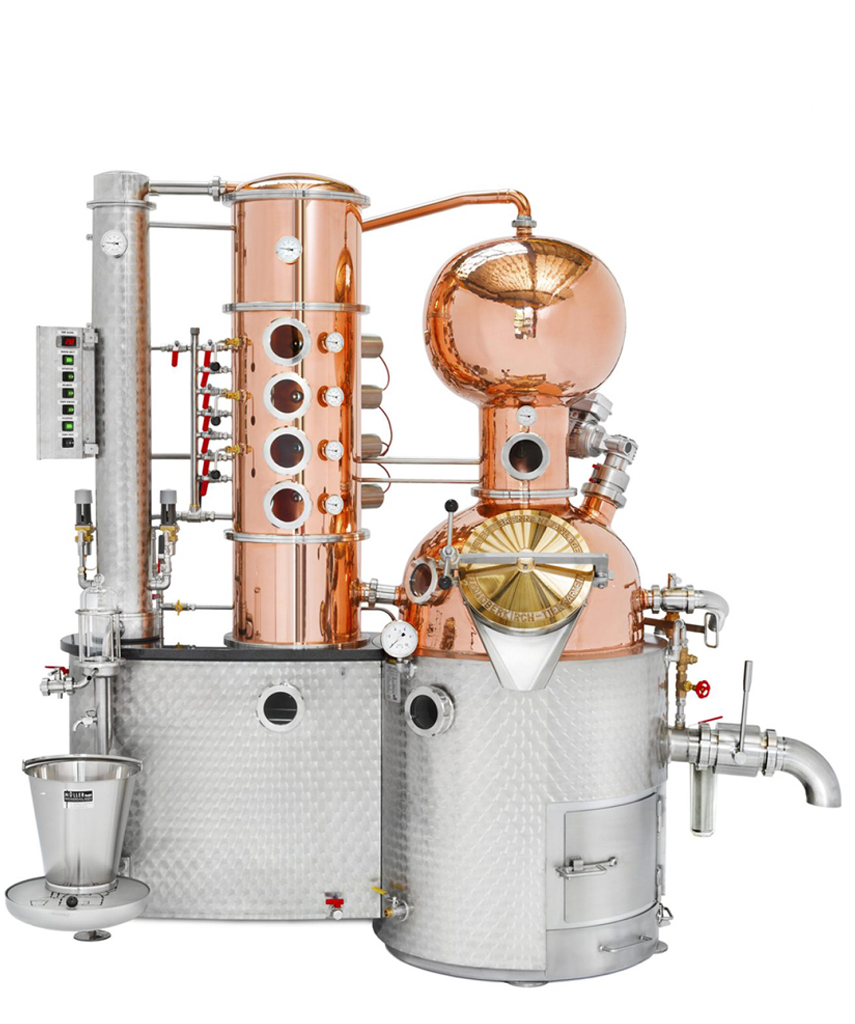

MÜLLER CONTROLS BASIC

All the basic functions of an automated distillery control system.

MÜLLER Controls Basic

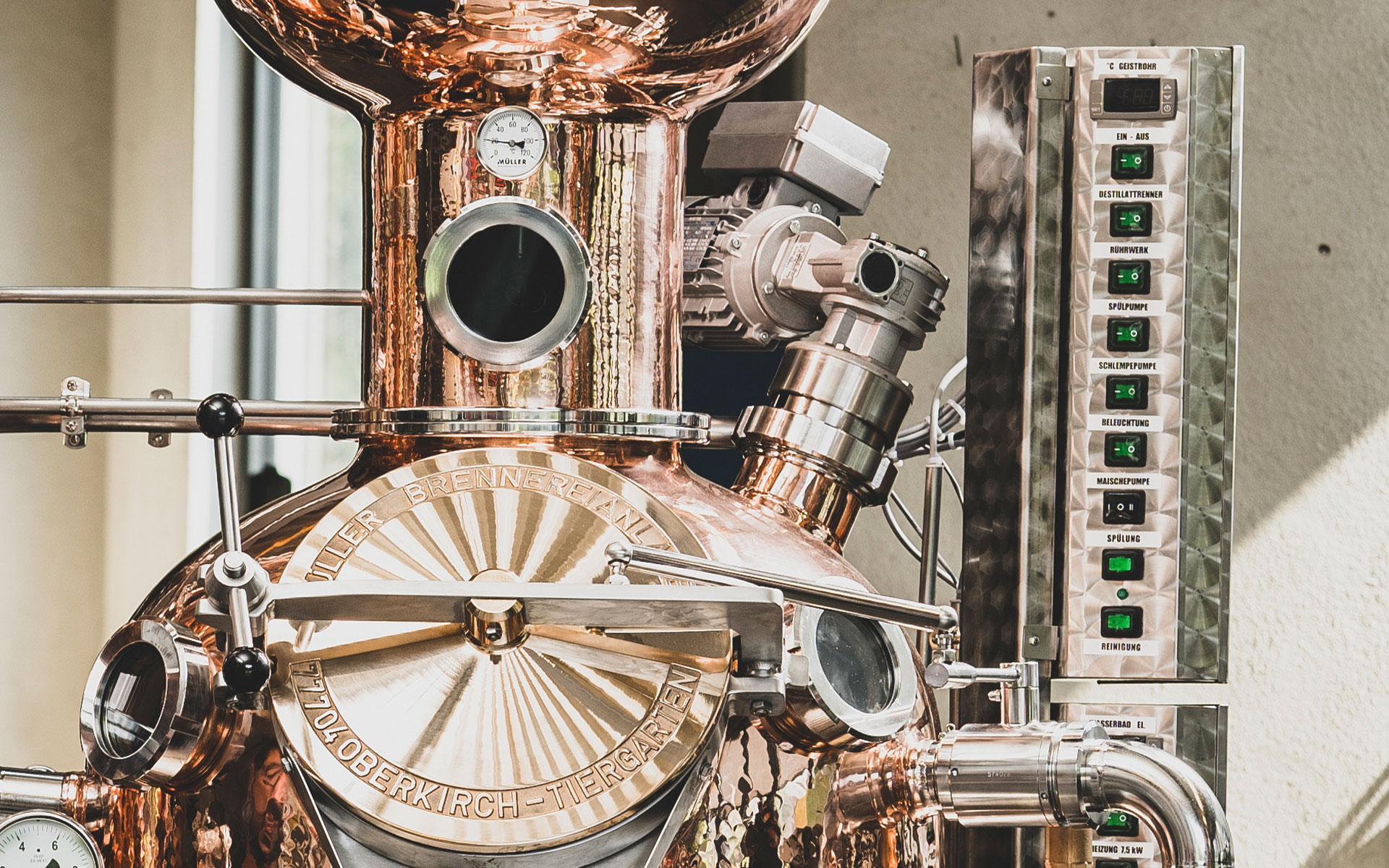

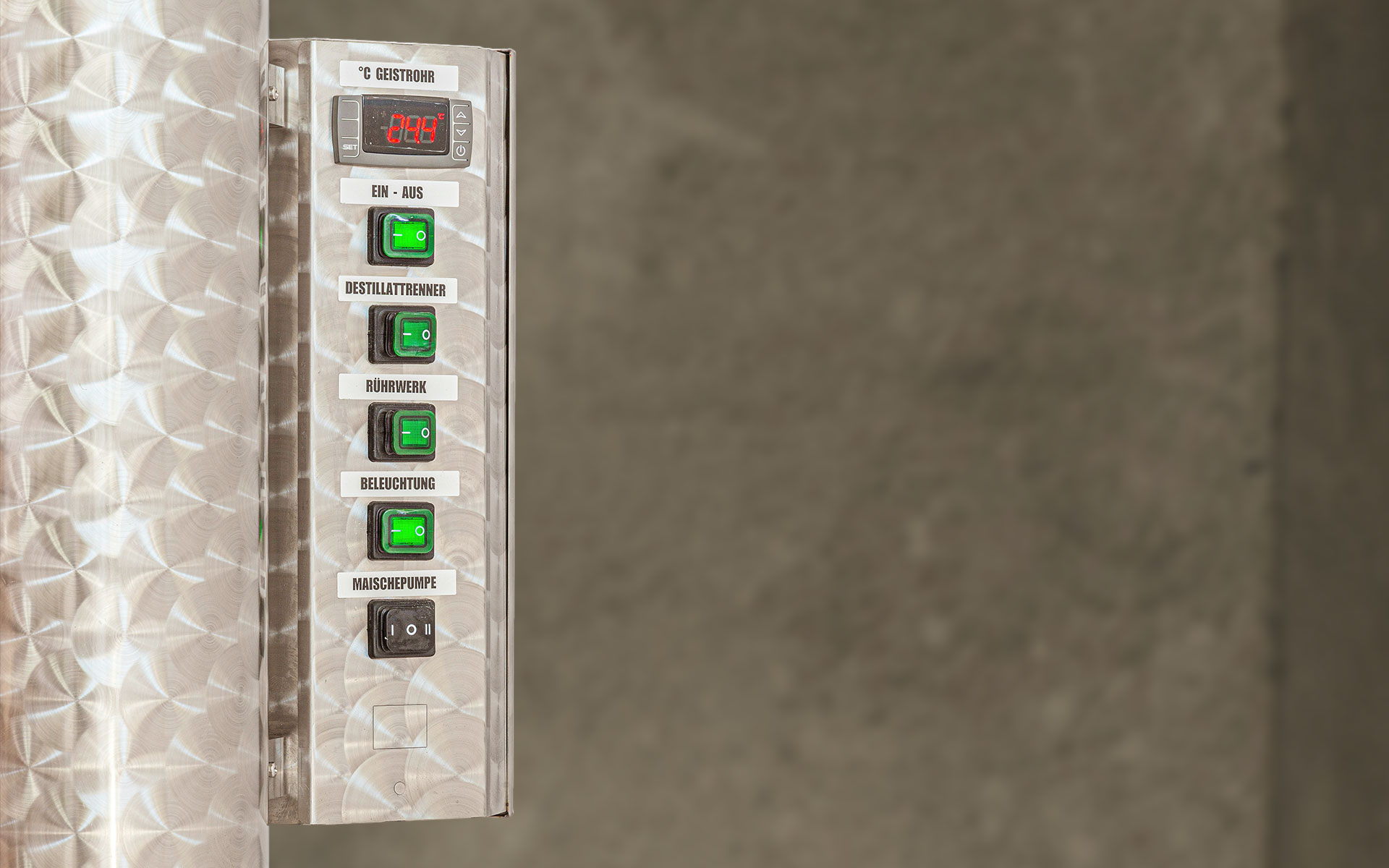

User-friendly control of motors, pumps and electric valves via an analog control panel with MÜLLER Controls Basic. Keep track of running distillation processes with the digital temperature displays. Optional: Semi-automated distillation with the distillate separator.

Product features:

- Analog switching of pumps, agitator and lighting

- Temperature monitoring

- Safety thermostat as a safety component in the event of a lack of cooling water

Optional:

- Electric heating

- Distillation separation

- Agitator with frequency converter

- Automatic flushing system

Applications:

- Settlement distilleries

- De-powering systems

- Sealing distilleries

Your advantages:

- Can be retrofitted to existing systems

- Individual adaptations to customer requirements

Retrofittable.

Automated cleaning

Product features

- Cleaning process using solenoid valves

- Short rinsing time (standard cleaning)

- Long rinsing time (dry cleaning)

Areas of application

- Settlement distilleries

- De-powering systems

- Sealing distilleries

- Mashing and fermentation plants

Your advantages

- Can be retrofitted to existing systems

- Making work easier

- Quality assurance

Fractional separation

Product features

- Manual or automated fraction separation

- Flow quantity recording

- Downstream separation based on spirit tube temperature

Areas of application

- Settlement distilleries

- De-powering systems

- Sealing distilleries

Your advantages

- Can be retrofitted to existing systems

- Reproducible distillates

- Quality assurance

MÜLLER Controls in comparison.

TECHNICAL DETAILS | Basic | Smart | Pro |

|---|---|---|---|

| Control of motors/pumps/lighting | x | x | x |

| Temperature monitoring in the water bath/hat/spirit tube | x | x | x |

| Main switch/emergency stop switch | x | x | x |

| Manual control of the heat output (electric, gas or steam) | x | x | x |

| Safety thermostat for safety shutdown in the event of a lack of cooling water | x | x | x |

| Distillation separation of inlet, middle run and outlet | x | x | x |

| Automated cleaning process (CIP) | x | x | x |

| Operating hours recording and fire counter | x | x | x |

| Status messages as push notifications on any end device (prerequisite: network connection) | x | x | |

| Visualization of the distillation processes on a mobile device | x | x | |

| Visualization via touch display | x | x | |

| Automated filling and emptying of the still | x | ||

| Automated heat output control | x | ||

| Recipe management | x | ||

| Remote maintenance via secure VPN connection | x | ||

| Alarm management | x | ||

| Single mash automation option | x | ||

| Fermentation control option | x |

MÜLLER

Controls in comparison.

We provide personal and custom advice!

Our MÜLLER quality standard always includes individual and custom advice on your personal project.

We are looking forward to hearing from you.

Call us at +49 7802 / 93550 or send us an e-mail at info@brennereianlagen.de