Diluting

MÜLLER. Your one-stop supplier.

Diluting

After adequate time in storage, the distillate must be prepared for sale. This includes steps like the reduction of the high-proof distillate to drinking strength, as well as filtering.

Distillates can become cloudy as soon as they are diluted with water to a drinking strength of 38 - 45% vol. This makes it necessary to filter the distillate to remove cloudy substances and suspend particles and/or residues from barrel aging.

A very special distillate treatment is achieved with the patented CASCO process.

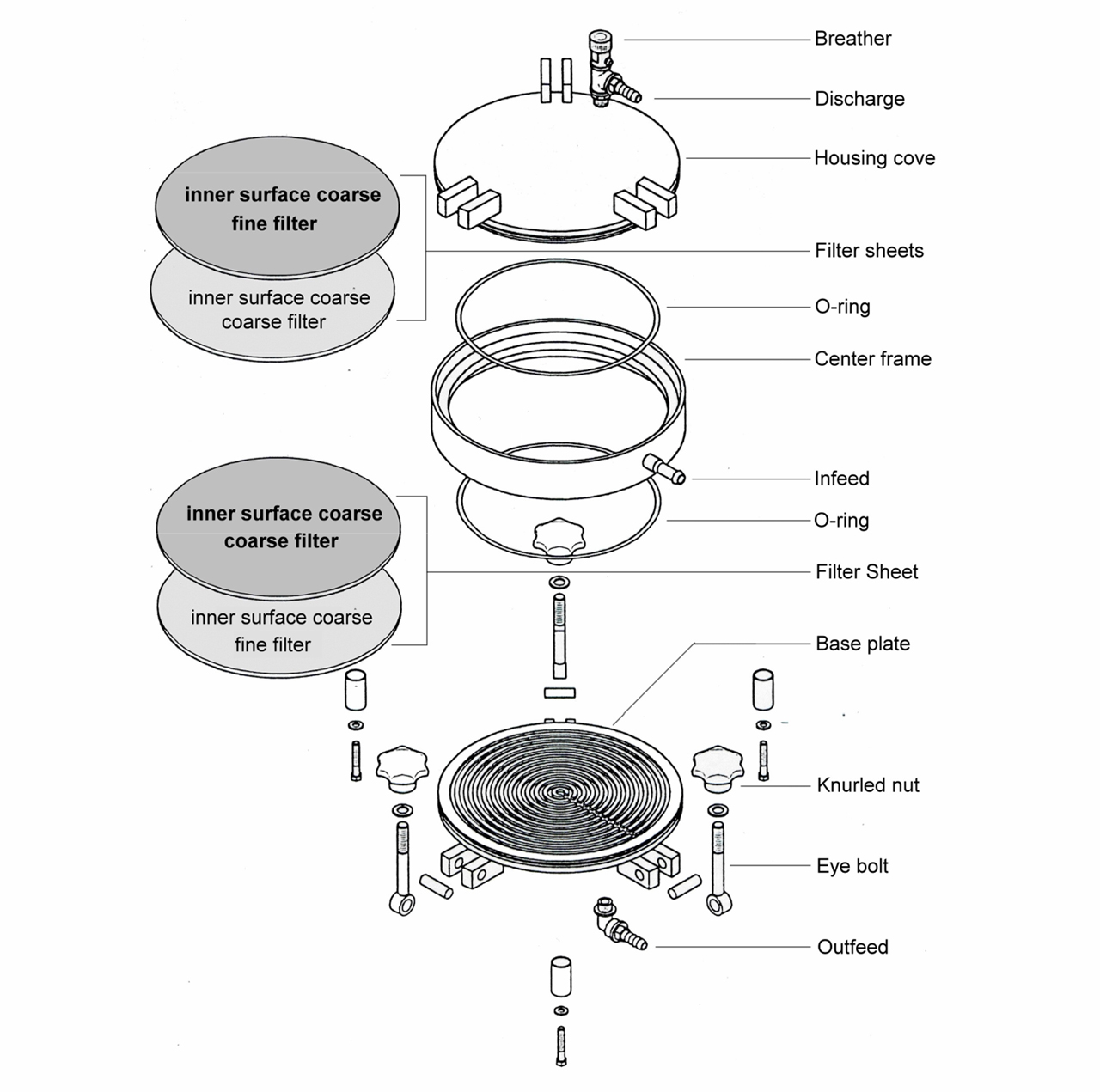

Round Filter

The gentle and safe filtration of distillates.

For quality-oriented filtration, we will couple the proven layered round filter with the pump that best suits your needs. The self-priming centrifugal pump is maintenance-free. A pressure gauge and a control valve allow you to individually adjust the filtration performance as required. Depending on the pump type, it can also be used as a liquor or wine pump.

We also stock the filter sheets suitable for your application purposes.

These filter sheets have a very low content of soluble ions and are especially developed for distillates and liqueurs.

We offer you two different sizes.

Item No. 27202

Round filter MFR 14, filter capacity 80l/h

Equipped with self-priming Speck or NOVAX pump

Round filter for max. 4 filter sheets D = 14 cm

Item No. 27201

Round filter MFR 22, filter capacity 130l/h

Equipped with self-priming Speck or NOVAX pump

Round filter for max. 4 filter sheets D = 22 cm

Casco

The patented CASCO process for distillate treatment allows further enhancement in quality for distillates and the elimination of small sensory mistakes. It enables the reduction of increased methanol and cyanide contents.

The patented CASCO process for distillate treatment promises a further increase in the quality of high-quality distillates and the elimination of minor sensory defects. It enables the reduction of elevated methanol and cyanide contents.

The system consists of a vessel with built in agitator and a specially shaped lid. The alcohol to be refined is filled into this tank. By heating the distillate in the vessel, volatile substances escape from the distillate. By cooling the lid at the same time, these vapours condense at its surface and are discharged that way.

While veiled fruit aromas develop a better sensory in high-quality distillates, aroma-relevant ingredient are not reduced. With faulty distillates, ingredients that are problematic to health such as methanol and cyanide contents are reduced. After the refinement treatment, the container can be cooled as well and serves as preparation for cold filtration.

The patented CASCO process for distillate treatment allows a further increase in quality for distillates and the elimination of small sensory mistakes. It enables the reduction of increased methanol and cyanide contents.

The system consists of a vessel with build in agitator and a specially shaped lid. The alcohol to be treated is filled into this tank. By heating the distillate in the vessel, volatile substances escape from the distillate. If the lid is cooled at the same time, these vapours condense at its surface and are removed that way.

While in high-quality distillates veiled fruit aromas develop a better sensory, aroma-relevant ingredient are not reduced. With faulty distillates, ingredients that are problematic to health such as methanol and cyanide contents are reduced. After treatment, the container can be cooled as well and serves as preparation for cold filtration.

We provide personal and custom advice!

Our MÜLLER quality standard always includes individual and custom advice on your personal project.

We are looking forward to hearing from you.

Call us at +49 7802 / 93550 or send us an e-mail at info@brennereianlagen.de