Während den Vorbereitungen der Junipalooza in Hamburg, haben sich Gin Foundry und Sebastian für ein Interview getroffen:

Quelle: Gin Foundry

As we gear up for the inaugural Junipalooza Hamburg we’ve been catching up with some of the most interesting, delicious and renowned German gin brands to get you up close and personal ahead of time.

We took some time out to chat to Sebastian Müller of Müller Brennereianlagen, a 4th generation German still manufacturer who, fortunately for us, has a better idea than almost anyone else of just how much distilling is taking place in his home country.

For those who don’t know who you are and Müller Brennereianlagen, can you tell us a little about what you do and the stills you make?

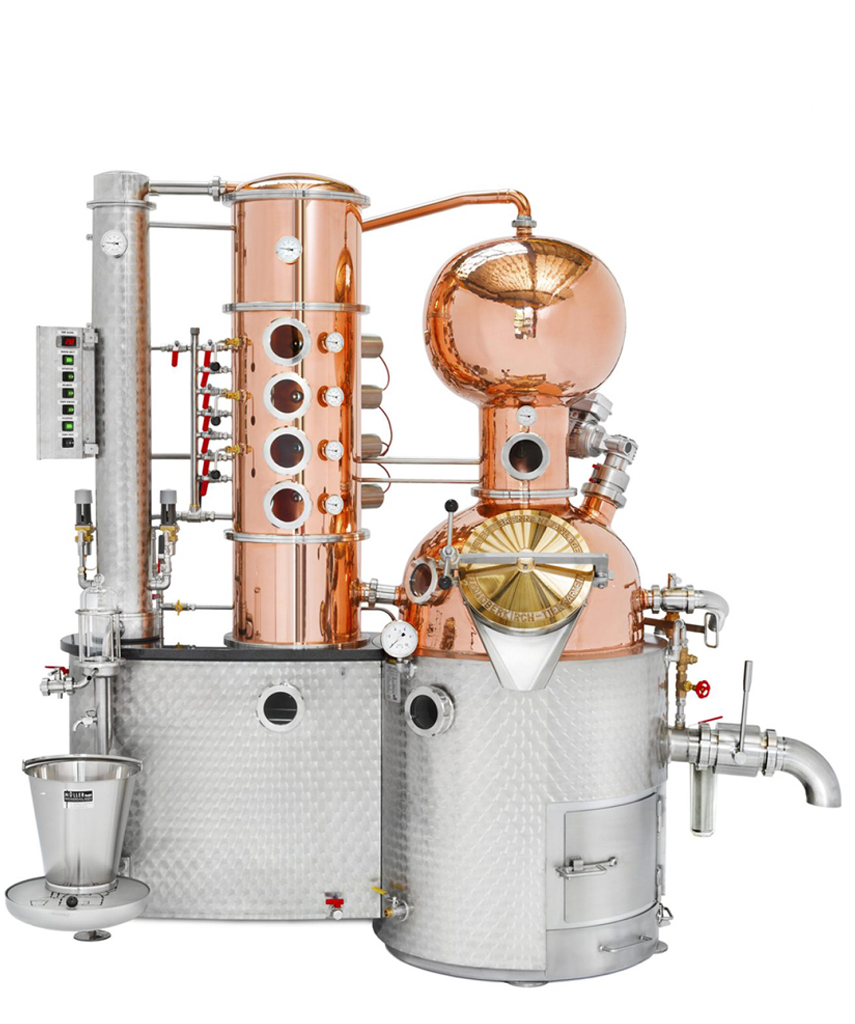

Müller Brennereianlagen is a pot still manufactures in its 4th generation. We are a family business with my parents, my brother and I, as well as 12 employees. We’re located in the black forest in Germany, an area which is known for its big distilling tradition especially for fruit brandies like “black forest cherry” “plums” or “Williams pear”. With around 15.000 stills in the area it might be the region with the largest “distillers population” worldwide.

Fifteen thousand stills is a lot of copper! Did you guys pursue a specific angle to cater to that market?

As mashing and distilling fruits is one of the most challenging aspects of making many of these traditional products, we have been focusing with our stills on technical improvements to extract as much flavour as possible out of the mash. With this mission in mind we developed special columns like the aRoMat and our unique rectification plates alongside other technical elements to increase performance.

When I think back to the old days when my grandfather was still the boss at Müller Brennereianlagen we sold our stills almost exclusively regionally. Of course we also had already a few customers in Italy, Austria and Switzerland as well, but that’s about it. Nowadays we are a global player in the distilling business. Our stills can be found from Australia to the Europe, from Iceland to Argentina. We got successful customers in Ethiopia, Sri Lanka, French Polynesia, Canada the USA. No matter this worldwide success we are still a manufactory where all stills are handcrafted and hand hammered while each unit is individually planned and built accordingly to the customer’s wishes as well as the spatial conditions. All starts with copper and stainless steel plates and after about 2-3 weeks with hammering, welding, polishing and many other steps and new still is build.

Surely by smashing it all by hand, it limits the capacity a little, do you have to focus on the smaller units?

To a certain extent, yes. Given the company size and the fact that all is handmade we are focusing on pot stills from 100 – 2.000 litres capacity.